Antimony and its compounds have a wide range of applications. They are mainly used in the production of ceramics, glass, batteries, paint, pyrotechnic materials, and flame retardants. In addition, they are also used in the production of semiconductors, infrared detectors, two-stage vacuum tubes, and insect repellents. With the widespread application of antimony and its compounds, the environmental problems caused by it have become more and more serious, and the research on antimony pollution at home and abroad is paying more and more attention. Antimony and its compounds are listed as a priority pollutant by the US EPA and also listed as hazardous waste by the Basel Convention. At present, the main methods for treating antimony-containing wastewater at home and abroad are chemical precipitation, ion exchange, adsorption, membrane filtration, and so on.

Activated carbon for antimony removal

Adsorption has a long history of material separation, which is often used to remove and recover trace pollutants in water. It has the advantages of high efficiency, simplicity, and good selectivity. Activated carbon has a developed pore structure, huge specific surface area, and good mechanical strength. Because of its good adsorption, it is widely used in wastewater treatment. At present, the removal rate of special heavy metal (such as antimony) is relatively low, but when the wastewater passes through Ultrasound and is then adsorbed by activated carbon, it is found that ultrasound can significantly promote the treatment of antimony in wastewater by activated carbon.Antimony removal test

The study took Sb as the target pollution and discussed the treatment effect of activated carbon on it under the action of ultrasound. The effect of adsorption temperature on adsorption efficiency Prepare several 2mg/L, 100mL Sb solutions, sonicate for 20min at 40℃, add 200mg of activated carbon after sonication, shake and absorb at 30, 35, 40, 45, 50, 55, and 60℃ for 60 min, and shake at 250r/min. After the adsorption is over, measure the remaining Sb content in the solution and calculate the Sb removal rate. The results are shown in the table below.| Adsorption temperature(℃) | Removal rate(%) | Adsorption temperature(℃) | Removal rate(%) |

| 30 | 90.96 | 50 | 90.45 |

| 35 | 90.19 | 55 | 90.83 |

| 40 | 90.71 | 60 | 90.54 |

| 45 | 90.58 |

It can be seen from the table that during the adsorption process, the removal rate of antimony tends to be stable with the change of adsorption temperature. Therefore, the adsorption temperature has little effect on the adsorption effect.

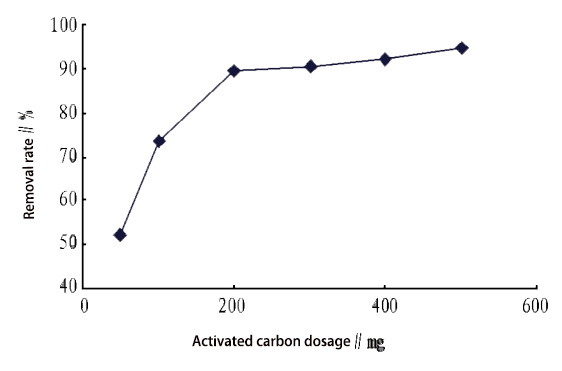

The effect of activated carbon dosage on adsorption efficiency

Prepare several portions of 2mg/L, 100ml Sb solution, sonicate for 20min at 40℃, add activated carbon 50, 100, 200, 300, 400, 500mg after sonication, shake and absorb for 60min, shake rotation speed is 50r/min, after the end of the adsorption, measure the remaining Sb content in the solution, calculate the Sb removal rate, and the result is shown in the figure

In the adsorption process, as the dosage of activated carbon increases, the concentration of adsorbed ions in the solution decreases, and the removal rate of antimony ions increases rapidly. However, when the dosage of activated carbon is greater than 200mg, even adding more the dosage of activated carbon, and the removal rate of antimony ions is increasing slowly. Therefore, considering the cost factor, the optimal dosage of activated carbon for treating 2mg/L, 100ml antimony solution is 200mg, and the best ratio of Sb content to activated carbon is 1mg Sb/g activated carbon.

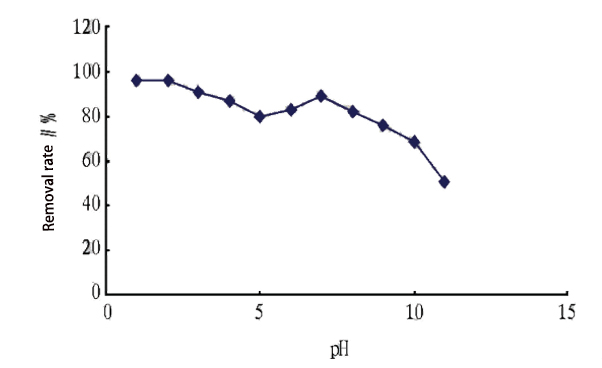

The effect of PH on adsorption efficiency

Prepare several 2mg/L, 100ml Sb solutions, adjust the pH to 1, 2, 3, 4, 5, 7, 8, 9, 10, 11, and sonicate at 40°C for 20 minutes, add 200 mg each after the sonication, and oscillate at a speed of 250r/min, after the adsorption is over, measure the remaining Sb content in the solution and calculate the Sb removal rate, as shown in the figure below.

It can be seen from the figure that PH has a greater influence on the adsorption performance of activated carbon. In the range of PH from 1-11, the PH corresponding to the maximum adsorption removal rate is 1-2, and then as the PH increases, the removal rate tends to decrease. Therefore, the optimal PH of the test is 1-2, considering the processing cost, PH 2 is the best condition.

Which type of activated carbon is suitable for antimony removal?

Activated carbon removes antimony from water through adsorption, utilizing its highly porous structure and large surface area to capture antimony ions. The process involves both physical attraction and chemical bonding between antimony and the carbon surface. Coconut shell-based activated carbon is often effective due to its high microporosity, though iron-impregnated carbons can offer enhanced performance. The efficiency of removal depends on factors like pH, contact time, and the form of antimony present. The most suitable type of activated carbon for antimony removal should be selected based on specific water conditions and antimony concentrations.

Conclusion:

Studies have shown that ultrasonic waves can significantly promote antimony ions in the activated carbon treatment of wastewater. When using ultrasonic and activated carbon to treat antimony-containing wastewater, the ultrasonic time is 20min, the temperature is 40℃, the adsorption time is 60min, the pH is 2, and the ratio of activated carbon to antimony is 1mg Sb/g. The treatment effect of activated carbon is the best, and the removal rate is 95.86%.For those seeking reliable activated carbon solutions for antimony removal, Zhulin Carbon offers a range of high-quality products designed to meet diverse industry needs. With our 30 years of expertise in activated carbon production, we provide tailored solutions to address your specific antimony removal challenges. Contact Zhulin Carbon now to discuss your water treatment requirements and discover how our premium activated carbon products can enhance your antimony removal processes.