.png)

Activated carbon, known for its exceptional adsorption properties, has emerged as a powerful tool for treating and purifying waste engine oil. By effectively removing contaminants and impurities, activated carbon enables the recycling and regeneration of used engine oil, reducing waste and environmental impact. In this blog post, we will explore the benefits, process, and real-world applications of activated carbon filtration for waste engine oil, highlighting its role in promoting a more sustainable and eco-friendly approach to managing this valuable resource.

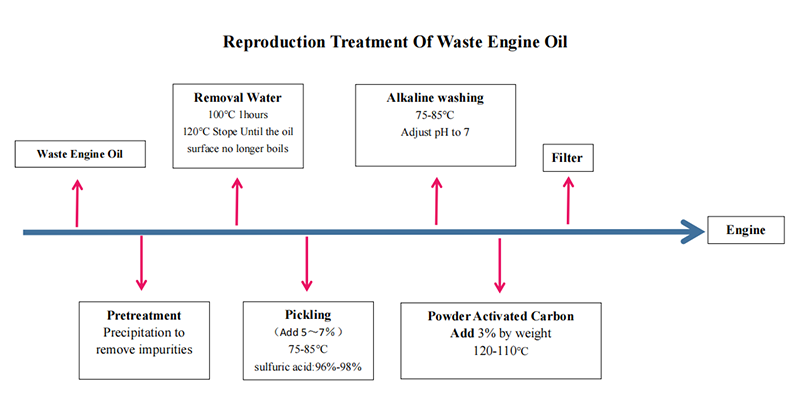

How to purify used engine oil?

Pretreatment

Before filtration, it's advisable to pre-treat the used engine oil to remove any large debris or solid particles. This can be done using methods like settling or centrifugation to separate out heavier impurities.

Removal water

Collect the waste engine oil in the oil collection tank, eliminating any water content. Transfer it to the refining pot and gradually heat it to 70-80℃. Once heated, allow it to stand for approximately 24 hours, enabling the separation of surface water. Then, slowly increase the temperature to 120℃, taking care to prevent boiling and overflow as the oil nears 100℃. During this process, allow the water to evaporate. After approximately two hours without stirring, you will observe the emergence of black oily gas from the oil's surface.

Pickling

Once the oil has cooled to room temperature, gradually introduce sulfuric acid (with a concentration of approximately 92-98%) while stirring. The amount of acid required typically ranges from 5-7% of the oil, depending on its level of contamination. After the addition of acid, continue stirring for thirty minutes, followed by a standing period of approximately 12 hours to allow for the drainage of acid residue.

Alkali washing

Reheat the pickled oil to 80℃, and while stirring, add soda ash (Na2CO3) ensuring thorough mixing. Allow it to stand for one hour, followed by testing its neutrality using test paper. Once confirmed neutral, let it stand for an additional four hours before draining the alkali slag.

Activated carbon adsorption

Heat the oil to a temperature range of 110-120℃, then introduce activated carbon (approximately 3.5% of the oil volume) while maintaining a stirring motion. Continue stirring for thirty minutes after adding the activated carbon, and subsequently stand for one night.

Filtration

The oil can be effectively filtered using an oil filter machine, resulting in the obtainment of high-quality oil. In the absence of an oil filter, an alternative method involves using a cloth bag hanging filter. The aforementioned steps outline the general operational process for purifying engine oil, although the specific approach should be tailored to the unique circumstances at hand. For instance, if there is minimal impurity water present, the initial step can be omitted. Similarly, if the oil exhibits a normal color following acid-base treatment, there may be no need for decolorization or absorption using activated clay.

What is the purpose of using activated carbon?

The purpose of using activated carbon for waste engine oil is to effectively remove contaminants and impurities, thereby improving the quality and usability of the oil. Activated carbon, with its highly porous structure and large surface area, has excellent adsorption properties.

When used in filtration systems, activated carbon can attract and bind various organic compounds, heavy metals, sludge, and other pollutants present in used engine oil. As the oil passes through the activated carbon bed, the contaminants are adsorbed and trapped within the carbon's porous structure, leaving behind purified oil.

By employing activated carbon filtration, the following benefits can be achieved:

Removal of impurities:

Activated carbon can effectively remove carbon deposits, dirt, varnishes, soot, and other solid contaminants that accumulate in used engine oil. It also helps to eliminate soluble impurities and dissolved contaminants, such as heavy metals and other harmful substances.

Improved oil quality:

The removal of impurities through activated carbon filtration results in improved oil quality. The purified oil exhibits enhanced lubricating properties, better thermal stability, and reduced viscosity. This, in turn, contributes to improved engine performance and longevity.

Environmental sustainability:

Activated carbon filtration facilitates the recycling and regeneration of used engine oil, reducing waste and environmental impact. By removing contaminants from the oil, it prevents the release of pollutants into the environment, promoting sustainable resource management and responsible waste disposal.

Cost savings:

Purifying used engine oil with activated carbon allows for its reuse, reducing the need for new oil production and lowering overall maintenance costs. This can be particularly beneficial for industries or businesses that generate a significant amount of waste engine oil.

Overall, the purpose of using activated carbon for waste engine oil is to purify and regenerate the oil, enhancing its quality, extending its usability, and contributing to environmental sustainability.

Conclusion about the activated carbon for engine oil

In conclusion, the use of activated carbon in the treatment of waste engine oil proves to be an effective and efficient method for purification. Activated carbon plays a crucial role in removing impurities, odors, and discoloration from the oil, resulting in the production of high-quality, usable oil.At Zhulin Carbon, we specialize in providing advanced solutions for the purification of waste engine oil using activated carbon. Our expertise and cutting-edge technologies ensure optimal results and environmental sustainability. By leveraging our services, you can not only recover valuable resources from waste oil but also contribute to the reduction of environmental pollution.

Contact us to learn more about our activated carbon-based purification services and how we can assist you in transforming your waste oil into a valuable resource.