Activated carbon is a highly effective material widely used in the purification and "polishing" of various types of oils. Whether it's edible oils, lubricants like engine oil, or crude petroleum, activated carbon plays a crucial role in improving the quality, removing impurities, and ensuring the safety and performance of the final product. In this blog, we will explore how activated carbon contributes to the refinement of three major types of oils: edible oils, engine oils, and petroleum..jpg)

Edible Oils

Edible oil polishing refers to the process of refining oils like soybean oil, palm oil, sunflower oil, and others to remove impurities, odors, and undesirable colors. The goal is to produce oils that are safe, clear, and appealing for consumption.

Activated carbon is used in the final stages of edible oil production to:

• Remove Odors and Toxins: It adsorbs volatile compounds and contaminants such as polycyclic aromatic hydrocarbons (PAHs) and pesticides.

• Improve Color: Activated carbon removes pigments and other colorants, resulting in light-colored, visually appealing oils.

• Enhance Shelf Life: By eliminating oxidation-causing impurities, activated carbon helps extend the storage life of edible oils.

So activated carbon can be used in filtering systems for oils such as olive oil, coconut oil, and vegetable oils, effectively removing trace contaminants that can impact the flavor and safety of cooking oils. By eliminating impurities, it helps produce clear, odor-free, and high-quality edible oils that meet stringent food safety and quality standards.

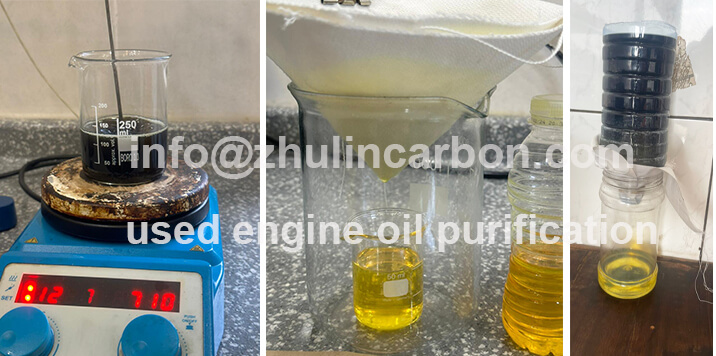

Engine Oils

Engine oil (engine oil or lubricants) needs to maintain its performance under high temperatures and extreme conditions. Over time, contaminants such as carbon deposits, heavy metals, and oxidation byproducts accumulate in the oil, reducing its efficiency. Polishing motor oil is essential not only during production but also for recycling used oil.

Activated carbon is used to:

• Remove Impurities: It adsorbs carbon deposits, heavy metals, and sludge from motor oil.

• Neutralize Acids: It helps remove acidic compounds formed during oil degradation, improving oil stability.

• Enhance Clarity: Activated carbon reduces turbidity and improves the appearance of motor oil.

So activated carbon cane be used in the production process to ensure high-quality lubricants and plays a key role in oil recycling and re-refining, making used motor oil reusable. By effectively removing impurities and contaminants, it extends the lifespan of motor oil, reduces waste, and promotes sustainability through efficient recycling practices.

Petroleum

Petroleum products like crude oil, diesel, gasoline, and jet fuel require extensive refining to meet quality and environmental standards. Impurities such as sulfur compounds, polycyclic aromatic hydrocarbons (PAHs), and heavy metals need to be removed to ensure product performance and reduce harmful emissions.

In the petroleum industry, activated carbon is used to:

• Remove Sulfur Compounds: It adsorbs sulfur-containing molecules like hydrogen sulfide (H2S) and mercaptans, reducing corrosion and improving fuel quality.

• Eliminate Aromatics: Removes harmful PAHs and other impurities to ensure cleaner and more efficient fuel combustion.

• Improve Color and Odor: Activated carbon removes odor-causing compounds and enhances the visual quality of petroleum products.

Activated carbon can be used during the refining process to purify crude oil and its derivatives, playing an essential role in producing cleaner fuels such as low-sulfur diesel and aviation-grade jet fuel. By effectively removing impurities, it helps produce high-performance fuels that meet environmental regulations and reduces harmful emissions, contributing to a greener and more sustainable energy industry.

Conclusion

Activated carbon is a versatile and reliable solution for oil polishing, capable of addressing the unique challenges of edible oil refining, waste motor oil recycling, and petroleum purification. Its ability to remove impurities, enhance quality, and ensure safety makes it an essential material across these industries.

At Zhulin Carbon, we specialize in providing high-quality activated carbon solutions tailored to your specific needs. Whether you’re a food processor, a recycling plant operator, or a petroleum refiner, activated carbon can help you achieve superior product quality while promoting sustainability and compliance with industry standards.