This article will explore the characteristics, sources and production process of nickel in depth, focusing on the important role of activated carbon in nickel recovery, and introduce how the special activated carbon produced by Zhulin Carbon Industry provides an efficient solution for nickel recovery.

What is nickel?

Nickel is a silvery-white metal with good ductility, magnetism and corrosion resistance. It is widely used in industrial machinery manufacturing, household goods, as well as aerospace, tanks and ships, nuclear reactors and other fields. With the rise of new energy vehicles, nickel has also become an important raw material for a variety of batteries such as ternary lithium batteries, nickel-hydrogen batteries, and nickel-cadmium batteries.Chemical properties:

• Corrosion resistance• Ferromagnetic

• Stable chemical properties at room temperature

• Can form alloys with a variety of elements

Nickel main applications:

• Stainless steel production: Nickel is an important component of stainless steel, improving the strength and corrosion resistance of steel.• Battery manufacturing: Nickel is used in both nickel-hydrogen batteries and lithium-ion batteries.

• Electroplating: Used to improve the corrosion resistance and appearance of metal surfaces.

• Catalyst: Used as a catalyst in the chemical industry.

• Aerospace: Used to make high-temperature resistant alloys.

• Electronic products: Used to make electronic components and connectors.

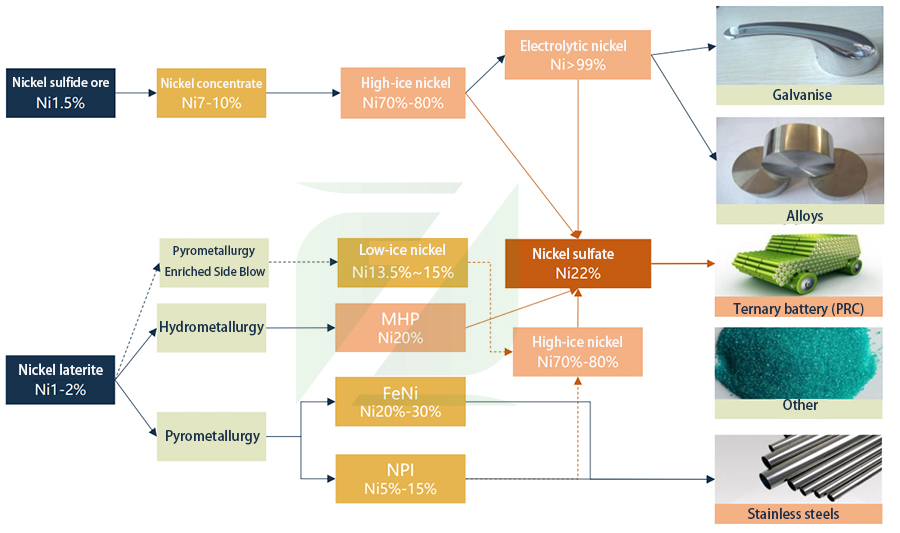

Nickel production process

Among the global nickel resources, about 60% exist in the form of laterite nickel ore. With the growth of nickel demand for stainless steel and new energy, laterite nickel ore has gradually become the main supply form of nickel resources due to its relatively rich reserves and low mining difficulty. At present, the smelting process of laterite nickel ore includes two major directions: pyrometallurgy and hydrometallurgy. Generally, pyrometallurgy is suitable for silicon-magnesium nickel ore with relatively high nickel content, and hydrometallurgy is suitable for limonite nickel ore with relatively low nickel content. In the hydrometallurgy process, compared with ammonia leaching and atmospheric pressure acid leaching, high pressure acid leaching (HPAL) has a higher recovery rate of nickel and cobalt, which is the mainstream direction of the development of hydrometallurgy.

HPAL

HPAL is a hydrometallurgical process for treating low-grade nickel ores, especially laterite nickel ores. HPAL uses the strong leaching ability of sulfuric acid under high temperature and high pressure conditions to dissolve valuable metals such as nickel and cobalt in nickel ore into the solution. This process is usually carried out in an autoclave at a temperature of 240-270°C and a pressure of 3.5-5.5 MPa.HPAL Process flow:

a) Ore pretreatment: crushing, screening, pulpingb) Preheat and acid leaching: acid leaching in an autoclave

c) Solution flash distillation cooling

d) Neutralization: pH adjustment, iron, aluminium removal

e) Extraction separation: separation of metals such as nickel and cobalt

Zhulin activated carbon (Qizhong Chemical) plays a multifunctional key role in nickel mining and processing. From leachate purification to wastewater treatment, to gas purification and selective adsorption of metal ions, the efficient adsorption performance of Zhulin activated carbon runs through the entire production chain. It not only improves nickel recovery and product purity, but also plays an important role in environmental protection, ensuring that wastewater and exhaust gas emissions meet standards. For low-grade ores, Zhulin activated carbon can also be used in innovative enrichment processes. With its renewability and customizability, Zhulin Carbon's activated carbon products provide a cost-effective and environmentally friendly solution for the nickel mining industry.

Conclusion

As global demand for nickel continues to rise and environmental standards become increasingly stringent, efficient and clean nickel recycling technology becomes critical. Activated carbon plays a key role in the nickel recovery process due to its excellent adsorption performance and multifunctional properties. From leachate purification to wastewater treatment, activated carbon not only significantly improves the recovery rate of nickel, but also provides strong support for the environmental protection standards of the entire production process.As a pioneer in the activated carbon industry, Zhulin Carbon (Qizhong Chemical) Industry focuses on providing high-performance, tailor-made activated carbon solutions for the nickel recycling industry. Our products not only strictly meet technical requirements, but also help customers achieve dual improvements in economic benefits and environmental performance. If you are looking for activated carbon products to optimize the nickel recovery process, you are invited to contact Zhulin Carbon Industry. Our experienced technical team will provide you with professional consulting and customized services to help you stay ahead in the highly competitive market.