One of the most effective methods for MOH removal is activated carbon adsorption. This blog explores how activated carbon works, its benefits, and its applications in eliminating MOH contaminants.

What is MOH?

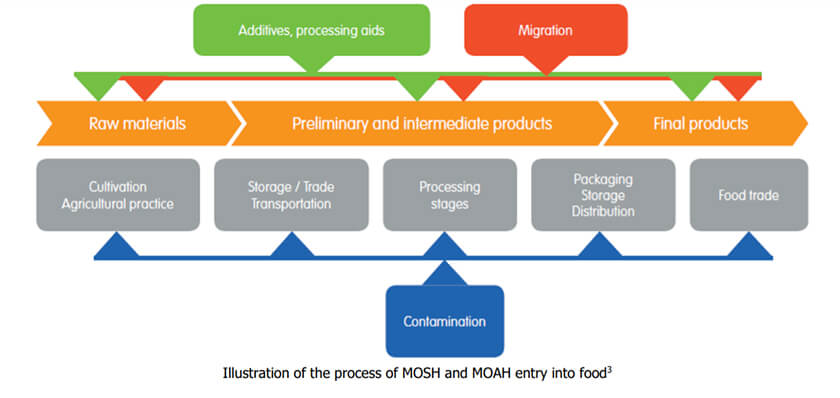

Mineral oil hydrocarbons (MOH) may exist in cereal foods, baked foods, oils, coffee and other foods. Common mineral oils include gasoline, diesel, kerosene, lubricating oil, white oil, wax oil, etc. MOH, especially MOAH, has potential carcinogenic and mutagenic properties and can enter food through environmental pollution, lubricating oils of food processing machinery, production aids, food additives and food contact materials, posing a threat to human health..jpg)

They can contaminate food products through:

• Packaging Materials: Recycled cardboard or inks used in printing food packaging.

• Processing Equipment: Lubricants or greases used in food production lines.

• Environmental Contaminants: MOH can also enter food products through environmental exposure during production or storage.

How Activated Carbon Works?

Activated carbon is a highly porous material with an extremely large surface area. This porous structure allows it to adsorb a wide range of substances, including MOHs. Adsorption is a process where molecules of the MOH adhere to the surface of the activated carbon rather than being absorbed into its bulk, like in absorption.The carbon in activated carbon is activated through a process that creates countless tiny pores. These pores act like traps for the MOH molecules. When a liquid or gas containing MOH comes into contact with the activated carbon, the MOH molecules are attracted to the surface of the carbon and get stuck in these pores. This effectively removes the MOH from the medium, whether it's water or air.

| Item | Activated carbon powder |

| Size | 200mesh, 325mesh, as you need |

| Ash | 5% max |

| Methylene blue | 14,16,18.... |

| Iodine value | 800-1000mg/g |

| Moisture | 10% |

Conclusion

Activated carbon is a proven, efficient solution for MOH removal in water, air, and food industries. Its high adsorption capacity, versatility, and cost-effectiveness make it a preferred choice for environmental and industrial applications.For optimal results, selecting the right type of activated carbon and maintaining proper filtration conditions are crucial. Contact us, if you have any question about MOH.