Introduction

Activated carbon is a highly porous, hydrophilic and chemically stable material that can adsorb large amounts of impurities and organic substances. In the sugar industry, activated carbon can be used to remove impurities such as pigments, proteins, and oxides in syrup, thereby improving the purity and quality of sugar.

Which activated carbon is best for color removal?

Powdered activated carbon uses high-quality wood chips as raw materials and is produced by the zinc chloride method. It has a developed mesoporous structure, large adsorption capacity, and rapid filtration. The appearance is black, non-toxic and odorless, with developed pores. It has the advantages of large specific surface area, strong adsorption capacity, fast filtration speed, and high decolorization purity. The characteristics of activated carbon for sugar are relatively developed micropores, mesopores and macropores.

Therefore, it can be widely used for sugar and food additives, such as:

• sucrose, maltose, glucose, maltose

• ribose, lactose, xylose, starch sugar

• citric acid, cystine, MSG, saccharin,

• optical brighteners, glycerin, vegetable oil,

• soy sauce, spices, beverages and food additives.

Why is activated charcoal used in sugar industry?

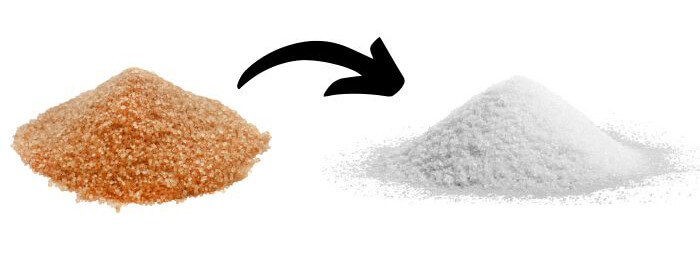

Sugar is a widely used food additive, and white sugar is one of the most common types of sugar. In the sugar industry, sugar mills need to extract sugar from raw materials and refine it into white sugar. However, due to the impurity of the raw materials and some impurities during processing, the produced sugar powder is often not completely white, which requires activated carbon for color removal. Activated carbon is a highly adsorbent and surface-active substance that can adsorb and remove impurities in syrup, such as colors, proteins, and organic acids, thereby making the syrup purer and meeting the requirements of refined white sugar. In the sugar industry, activated carbon is usually added to syrup in the form of dry powder, and after stirring and filtration, white powdered sugar is finally obtained.

How to choose activated carbon for sugar purification?

Sugars such as white sugar and brown sugar that we often see in our lives are extracted from plants and fruits with high sugar content and are produced through complex processes. Since when extracting sugar, pigments from plants will be brought into the sugar solution, there will definitely be a decolorization step when processing the sugar solution to help improve the quality of the sugar. Among them, the most commonly used is powdered activated carbon.

|

Activated carbon for color removal |

|||

|

Size |

200mesh |

||

|

Moisture |

10% min |

|

|

|

Caramel decolorization rate |

100 |

90 |

80 |

|

Ash |

3% |

4% |

5% |

|

Acid soluble matter |

1% |

1.5% |

2% |

|

PH |

3-5% |

||

How does the activated charcoal work in sugar purification?

The sugar industry refers to an industry that uses sugar cane, sugar beets, corn, etc. as raw materials to produce sugar products. In the sugar making process, activated carbon is often used as an important auxiliary material. Activated carbon has extremely strong adsorption capacity and solubility, so in the sugar industry, it can be used to remove impurities and pigments in syrup and improve the purity and clarity of syrup.

Specifically, the main functions of activated carbon are reflected in the following two aspects.

• Activated carbon has a strong adsorption effect in water and can absorb impurities, pigments and odor substances in syrup, thereby effectively purifying syrup.

• Activated carbon also has a catalytic effect, which can help some chemical reactions in the syrup proceed faster and improve the quality of the syrup.

The adsorption and catalytic properties of activated carbon are utilized in the sugar industry, which can effectively improve the purity and clarity of syrup, improve the quality of sugar products, ensure that products comply with national health standards, and play a positive role in our lives.

How do you Decolorize with activated charcoal?

The specific operation is to add activated carbon into the syrup to effectively adsorb and remove impurities in the syrup through oxidation, reduction, adsorption, etc. Using activated carbon for decolorization can make the syrup more transparent and increase the market value of the product. It is worth noting that choosing the appropriate activated carbon has a great impact on the decolorization effect. Different activated carbon materials have different pore structures and adsorption capabilities. It is necessary to select the appropriate activated carbon type and dosage according to the impurity characteristics and concentration in the syrup, otherwise it will reduce the quality of syrup.

• Add 0.1%-3% activated carbon powder into the syrup and stir for 30-60 minutes

• The general use temperature of activated carbon is 75℃-80℃

• The application effect is better when the pH is 3-6.

• Do not add activated carbon to boiling solutions, as this may cause the risk of boiling.

Conclusion

Activated carbon plays a vital role in the sugar industry, particularly in the decolorization process, which is essential for enhancing syrup purity, reducing energy consumption, and ensuring production safety. To achieve effective decolorization, sugar manufacturing enterprises must prioritize the quality of activated carbon, opting for premium-grade options to maintain product excellence and competitive advantage. Choose Zhulin Carbon for superior activated carbon products, ensuring greater success in your sugar industry!